MARSHALL METHOD OF ASPHALT-CONCRETE MIX DESIGN

(You can download Pro-Forma link given in the end of this page)

you can also read Marshall Mix design Graphs

you can also read Marshall Mix design Graphs

INTRODUCTION:-

Bituminous

mixes (sometimes called asphalt mixes) are used in the surface layer of road

and airfield pavements. The mix is composed usually of aggregate and asphalt

cements. Some types of bituminous mixes are also used in base course. The design of asphalt paving mix, as with the

design of other engineering materials is largely a matter of selecting and

proportioning constituent materials to obtain the desired properties in the

finished pavement structure.

The desirable properties of Asphalt mixes are:

1.

Resistance to permanent deformation: The mix should not distort or be displaced

when subjected to traffic loads. The

resistance to permanent deformation is more important at high temperatures.

2. Fatigue

resistance: the mix should not crack

when subjected to repeated loads over a period of time.

3.

Resistance to low temperature cracking.

This mix property is important in cold regions.

4.

Durability: the mix should contain

sufficient asphalt cement to ensure an adequate film thickness around the

aggregate particles. The compacted mix

should not have very high air voids, which accelerates the aging process.

5.

Resistance to moisture-induced damage.

6. Skid

resistance.

7.

Workability: the mix must be capable of

being placed and compacted with reasonable effort.

8. Low noise

and good drainage properties: If the mix is to be used for the surface

(wearing) layer of the pavement structure.

Marshall

Stability and Hveem stabilometer tests are largely used for the routine

testing. Criteria for the suitable mix

design have been specified by the Asphalt Institute.

OBJECTIVE:- To design the Asphalt concrete mix using Marshall method.

MARSHALL

METHOD OF MIX DESIGN:-

In this

method, the resistance to plastic deformation of a compacted cylindrical

specimen of bituminous mixture is measured when the specimen is loaded

diametrically at a deformation rate

Of 50 mm per

minute. There are two major features of

the Marshall method of mix design. (i)

density-voids analysis and (ii) stability-flow tests. The Marshall stability of the mix is defined

as the maximum load carried by the specimen at a standard test temperature of

60°C. The flow value is the deformation that the test

specimen undergoes during loading upto

the maximum load. Flow is measured in

0.25 mm units. In this test, an

attempt is made to obtain optimum binder content for the type of aggregate mix

used and the expected traffic intensity.

STEPS OF

DESIGN:-

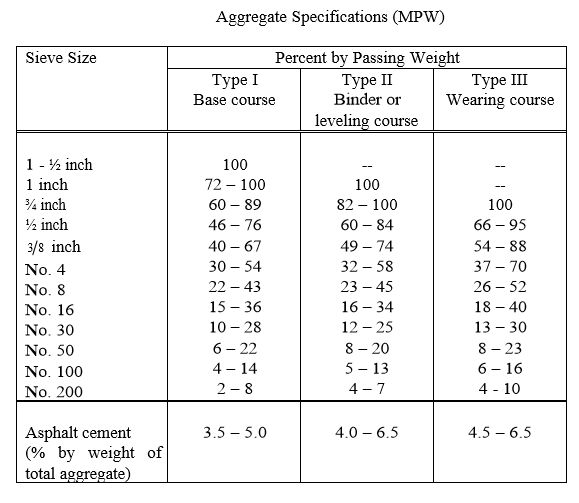

1. Select

aggregate grading to be used (Table 11.2)

2. Determine

the proportion of each aggregate size required to produce the design grading.

3. Determine

the specific gravity of the aggregate combination and asphalt cement.

4. Prepare

the trial specimens with varying asphalt contents.

5. Determine

the specific gravity of each compacted specimen.

6. Perform

stability tests on the specimens.

7. Calculate

the percentage of voids, and percent voids filled with Bitumen in each

specimen.

8. Select

the optimum binder content from the data obtained.

9. Evaluate

the design with the design requirements.

APPARATUS:-

1. Mold

Assembly: cylindrical moulds of 10 cm

diameter and 7.5 cm height consisting of a base plate and collar extension

2. Sample

Extractor: for extruding the compacted

specimen from the mould

3.

Compaction pedestal and hammer.

4. Breaking

head.

5. Loading

machine

6. Flow

meter, water bath, thermometers

In the Marshall test method of mix design three compacted samples are

prepared for each binder content. At

least four binder contents are to be tested to get the optimum binder

content. All the compacted specimens are

subject to the following tests:

• Bulk density determination.

• Stability and flow test.

• Density and voids analysis.

Preparation of

test specimens:-

The coarse aggregate, fine aggregate, and the filler material should

be proportioned so as to fulfill the requirements of the

relevant standards. The required

quantity of the mix is taken so as to produce compacted bituminous mix

specimens of thickness 63.5 mm approximately.

1200 gm of aggregates and filler

are required to produce the desired thickness. The aggregates are heated to a temperature of

175° to 190°C the compaction mould assembly and rammer are cleaned and kept

pre-heated to a temperature of 100°C to 145°C.

The bitumen is heated to a temperature of 121°C to 138°C and the required

amount of first trial of bitumen is added to the heated aggregate and

thoroughly mixed. The mix is placed in a

mould and compacted with number of blows

specified. The sample is taken out of

the mould after few minutes using sample extractor.

The bulk density of the sample is usually determined by

weighting the sample in air and in water.

It may be necessary to coat samples with paraffin before determining

density. The specific gravity Gbcm of

the specimen is given by

Stability test:-

In conducting the stability test, the specimen is immersed in a bath of

water at a temperature of 60° ± 1°C for a period of 30 minutes.

It is then placed in the Marshall stability testing machine (Fig. 7.1)

and loaded at a constant rate of deformation of 5 mm per minute until

failure. The total maximum in kN (that

causes failure of the specimen) is taken as Marshall Stability. The stability value so obtained is corrected

for volume (Table 11.1). The total

amount of deformation is units of 0.25 mm that occurs at maximum load is recorded as Flow Value. The total time between removing the specimen

from the bath and completion of the test should not exceed 30 seconds.

RESULTS AND

CALCULATIONS:-

Following results and analysis is performed on the data obtained from

the experiments

Bulk specific

gravity of aggregate (Gbam):-

Since the aggregate mixture consists of different fractions of coarse

aggregate, fine aggregate, and mineral filler with different specific

gravities, the bulk specific gravity of the total aggregate in the paving

mixture is given as

Maximu

specific gravity of aggregate mixture (Gbam):-

The maximum specific gravity of aggregate mixture should be obtained as

per ASTM D2041, however because of the difficulty in conducting this experiment

an alternative procedure could be utilized to obtain the maximum specific

gravity using the following equation:

Percent voids

in compacted mineral aggregate (VMA):-

The percent voids in mineral

aggregate (VMA) is the percentage of void spaces between the granular particles

in the compacted paving mixture, including the air voids and the volume

occupied by the effective asphalt content.

Percent air voids in compacted mixture (Pav):-

Percent air voids in compacted mixture (Pav):-

Percent air voids is the ratio

(expressed as a percentage) between the volume of the air voids between the

coated particles and the total volume of

the mixture.

DETERMINATION OF OPTIMUM BINDER CONTENT:-

DETERMINATION OF OPTIMUM BINDER CONTENT:-

Five separate smooth curves are

drawn with percent of asphalt on x-axis and the following on

y-axis

• unit weight

• Marshall stability

• Flow

• VMA

• Voids in total mix (Pav)

Optimum binder content is selected as the average binder content for

maximum density, maximum stability and specified percent air voids in the total

mix. Thus

The overall objective of the mix design is to determine an optimum

blend of different components that will satisfy the requirements of the given

specifications ,This mixture should have:

1. Adequate amount of asphalt to ensure a durable pavement.

2. Adequate mix stability to

prevent unacceptable distortion and displacement when traffic load is applied.

3. Adequate voids in the total compacted mixture to permit a small

amount of compaction when traffic load is applied without bleeding and loss of

stability.

4. Adequate workability to facilitate placement of the mix without

segregation.

If the mix design for the optimum binder content does not satisfy all

the requirements of specifications, It is necessary to adjust the original

blend of aggregates. The trial mixes can

be adjusted by using the following guidelines.

1. If low voids : The voids can be increased by adding more

coarse aggregates.

2. If high voids : Increase the amount of mineral filler in the

mix.

3. If low stability: This condition suggests low quality of

aggregates. The quality of aggregates

should be improved. (use different aggregate or use cement coated aggregate).

Thanks for information about Proforma Invoice. thanks for sharing keep it up!!!

ReplyDelete